|

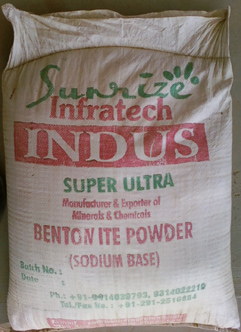

SODIUM BASED BENTONITE POWDER Sodium bentonite expands when wet, absorbing as much as several times its dry mass in water. Because of its excellent colloidal properties, it is often used in drilling mud for oil and gas wells and for geotechnical and environmental investigations. The property of swelling also makes sodium bentonite useful as a sealant, especially for the sealing of subsurface disposal systems for spent nuclear fuel and for quarantining metal pollutants of groundwater. Similar uses include making slurry walls, waterproofing of below-grade walls, and forming other impermeable barriers, e.g., to seal off the annulus of a water well, to plug old wells, or to line the base of landfills to prevent migration of leachate. It is also used to form a barrier around newly planted trees to constrain root growth so as to prevent damage to nearby pipes, footpaths and other infrastructure. Sodium bentonite can also be "sandwiched" between synthetic materials to create geo-synthetic clay liners (GCL) for the aforementioned purposes. This technique allows for more convenient transport and installation, and it greatly reduces the volume of sodium bentonite required. Bentonite is a clay mineral which is largely composed of Montmorillonite, which is mainly a hydrous aluminum silicate. It is highly colloidal and plastic clay with the unique characteristic of swelling to several times its original volume when placed in water. Mining then begins by removing the overburden from the mineral deposit with the use of large earth movers. The overburden is then stockpiled nearby for reclamation after the Bentonite has been removed from the bed. When contact with the bed is made, extreme care is taken to avoid contaminating the mineral deposit with the overburden, thus insuring the highest quality raw material. Care must also be taken to conserve as much Bentonite as possible when trimming the overburden from the Bentonite. When all the Bentonite has been removed from the bed, reclamation can begin. The surface of the mine site must be returned to equal or superior condition. The habitat for plant and animal is very important as are all other environmental considerations. |

|

|

PHYSICAL CHARACTERS: Properties Specification Recommended Uses: 1. Foundry Application : 2. Water well & Oil Well Drilling : 3. Construction and Civil Engineering : Other uses

Sodium bentonite is a natural sealant and is used for sealing stock and recreational ponds, dairy and sewage lagoons, and city landfills. It is also effective as a hole plug as well as for controlling dust on highways. Sodium bentonite is one of the "most effective law cost methods" of treating porous soils. It is so effective, that the Federal Government and most states require a liner of sodium bentonite or material comparable, to be used to seal toxic waste lagoons and abandoned water and oil wells. It is environmentally safe, because it contains no chemicals, no additives, nothing toxic. There are two types of Bentonite clay:- Bentonite is a highly versatile mineral. When processed carefully, it caters to a wide range of industries, from traditional usage areas such as metal casting, iron ore pelletizing, civil engineering, drilling, pet litter to speciality application areas such as paper, detergents, cosmetics etc. |

||

SODIUM BASED BENTONITE POWDER

.jpg)